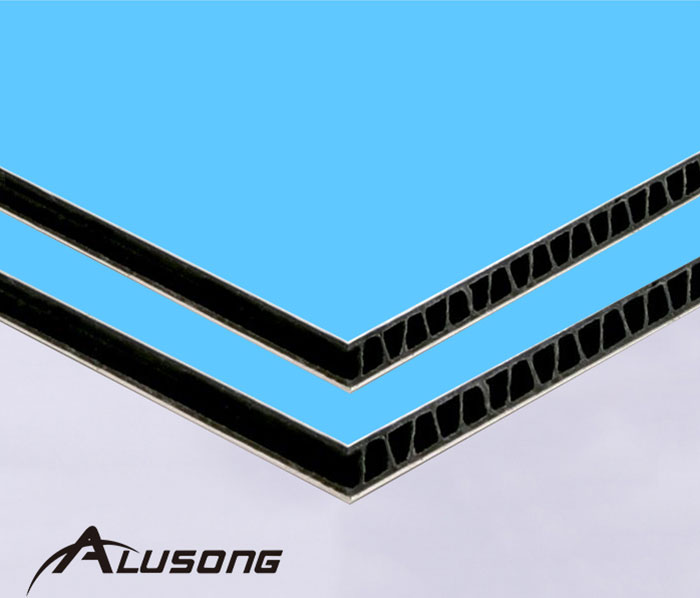

ALUSONG solid aluminum composite panel is a new composite material skinned with high solid aluminum sheets. Compare to the common panel, our engineer improve the product’s surface solid ,so it bring a vivid new look to the customers, which are very popular recently, especially are welcomed by...

| Aluminum | AA1100 AA3003 |

| Aluminum skin | 0.06mm,0.08mm,0.1mm,0.12mm ,0.15mm,0.18mm, 0.21mm,0.25mm, 0.30mm,0.35mm,0.40mm,0.45mm,0.5mm |

| Panel thickness | 2mm, 3mm,4mm,5mm,6mm/customize |

| Panel width | 915mm, 1220mm,1250mm, 1300,1500mm |

| Panel length | 2440mm, 3050mm, 3200mm, 4000mm, 5000mm/customize |

| Surface treatment | PE / PVDF / FEVE |

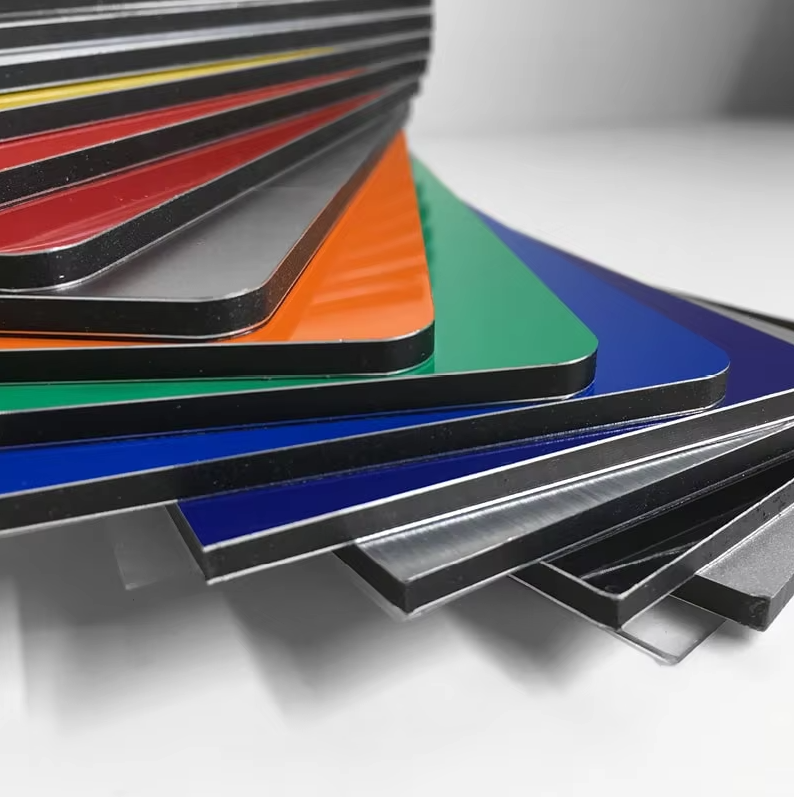

| Colors | 150 different colors / customize |

| Customers size | accepted |

Dimensional tolerance:

Panel width: ±2mm Panel length:±3mm

Panel thickness: ±0.2mm Panel diagonal: ≤5mm

Aluminum sheet thickness: ±0.01mm

Vivid colors

High resistance to peeling

Superior weather resistance

Light weight and easy to process

Coating evenness

Diversified colors

Easy for maintenance

Impact resistance

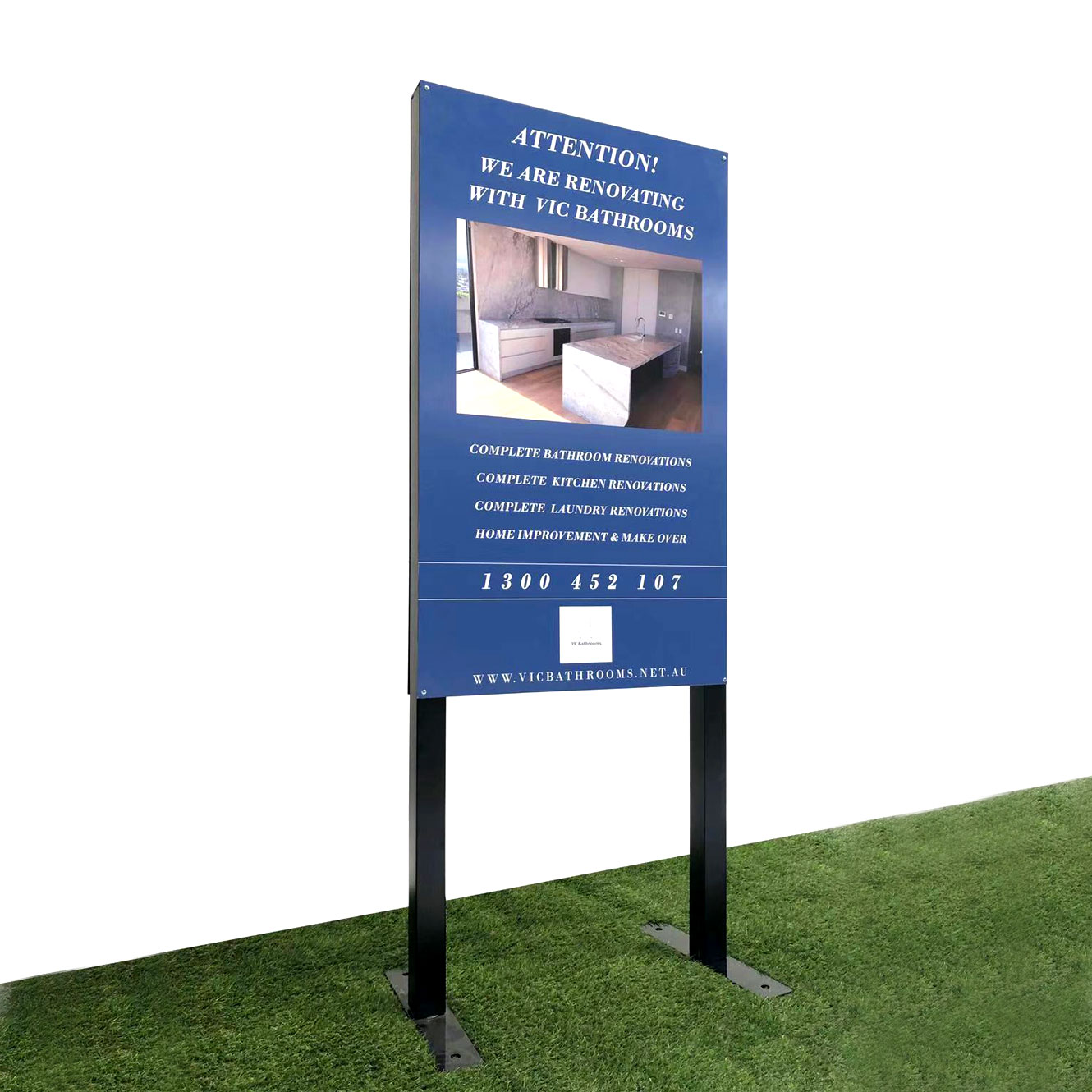

Sign Making, Shop Front

· Furniture &cabinets

· Standoff Lettering

· Interior decoration

· Cladding&facade

· Modular Sign Systems

· Exhibition Design

| Description | Test standard | Polyester |

| Thickness of coating | Polyester paint >=16um | 16um to 18um |

| Coating flexibility (T-bend) | Polyester paint≥3T | 3T |

| Color different | ΔE≦2.0(follow color sample) | ΔE≦2.0 |

| Pencil hardness | ≧HB | ≧2H |

| Chemical resistance | 2%HCI or 2%NaOH test in 24 hours -No change | No change |

| Coating adhesion | ≧1grade for 10810mm2gridding test | 1grade |

| Resist solvent | 100times with Dimethylebnzene without change | No change |

| Boiling water resistance | 2 hours without change | No change |

| Peeling strength/stripping strength | Average ≧5N/mm of 180oc peel off for panel with 0.21mm alu.skin | 5N/mm |

| Impact test for paint | 20KG.cm impact-paint no split for panel | No split |

| Abrasion resistance (L/Mil) | NIL | NIL |

| Temperature resistance | -40℃ to +80℃ temperature without change of color difference and paint peel off,peeling strength average dropprate≦10% | Change of glossy only,no paint Peel off |

| Cofficient of linear Thermal Expansion | 100℃ temperature difference | 2.4mm/n |

| Detergent resistance (3%) | ASTM D2248 | No change |

| Humidity Resistance (3000hrs,100%RH,100°F) | ASTM D2247 | No change |

| Salt spray resistance (3000hrs,5% salt) | ASTM B117 | No change |

| Resistance to Staining | 600h radiate in 800W/M2 in humidity condition,glossiness deviation less grade 2,color difference ≦4.0 | No change |