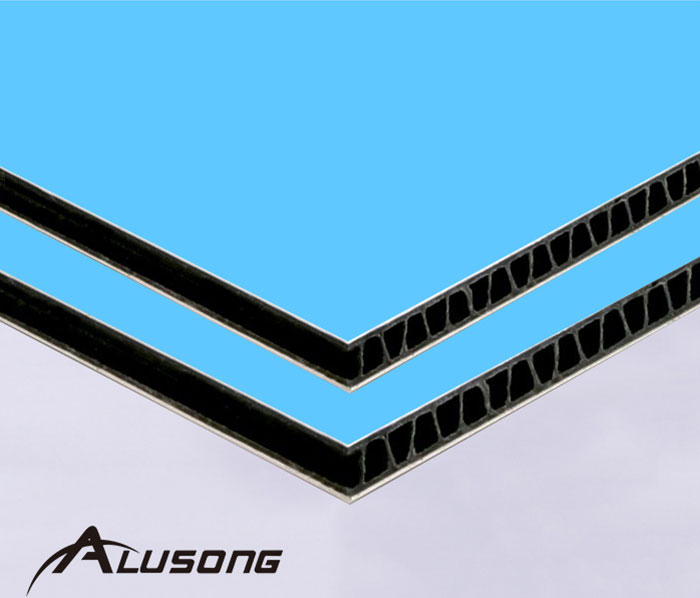

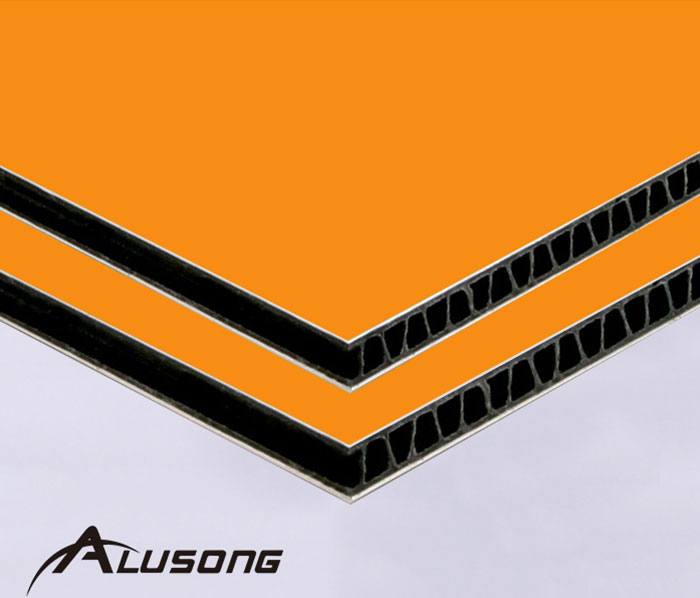

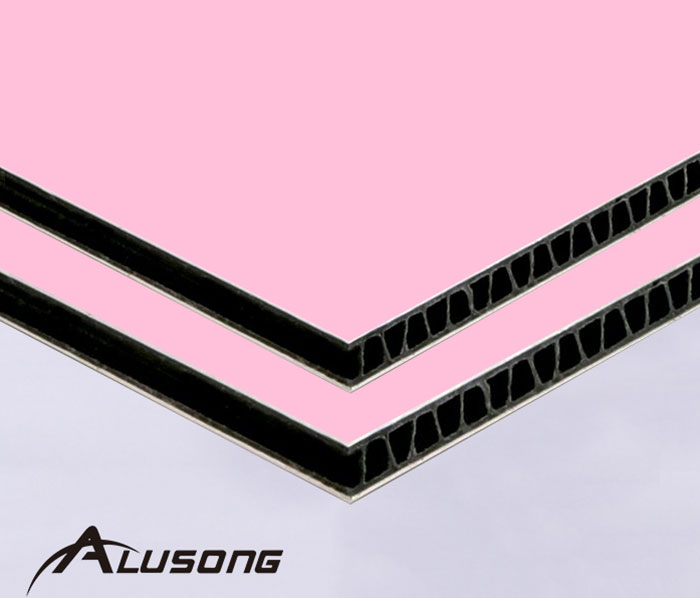

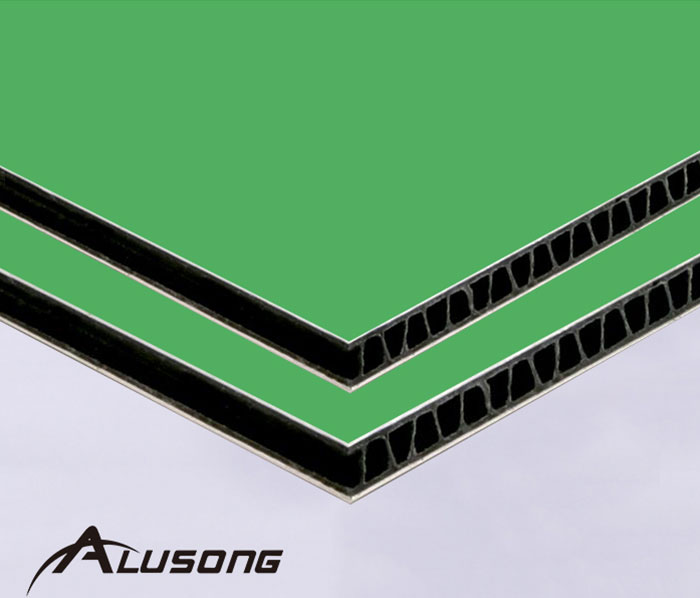

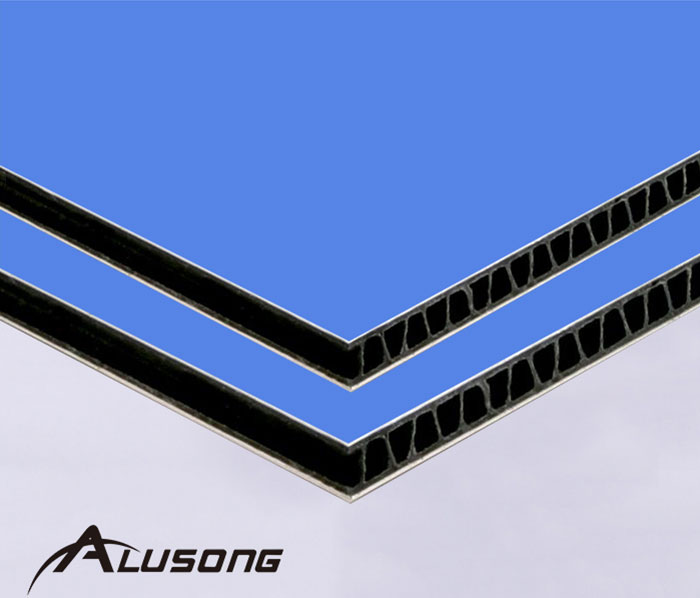

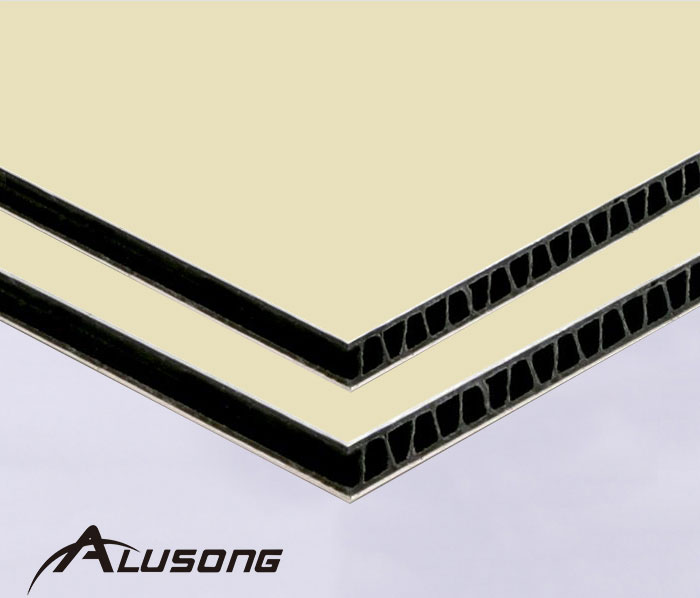

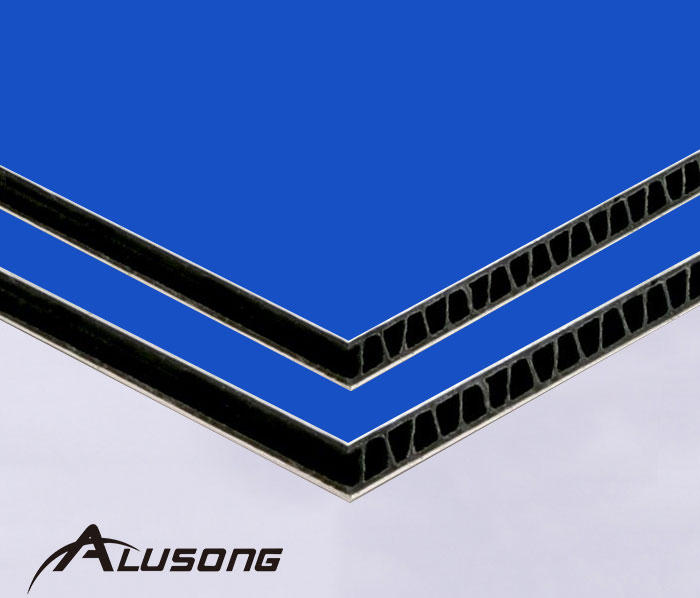

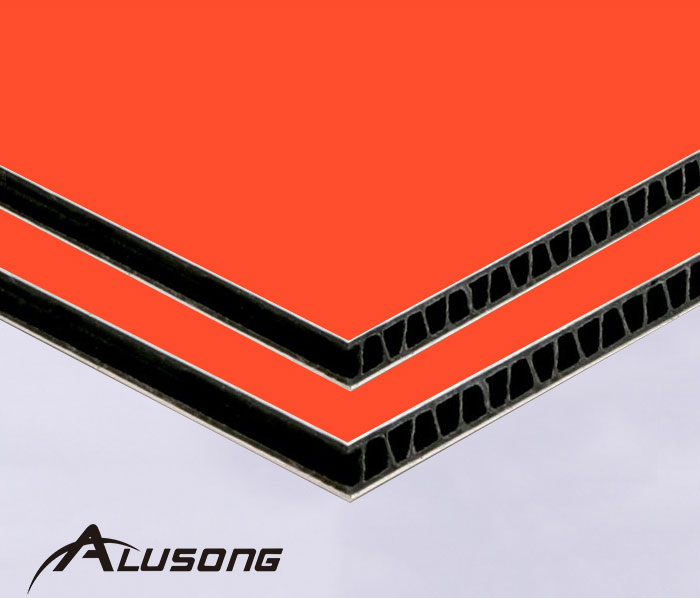

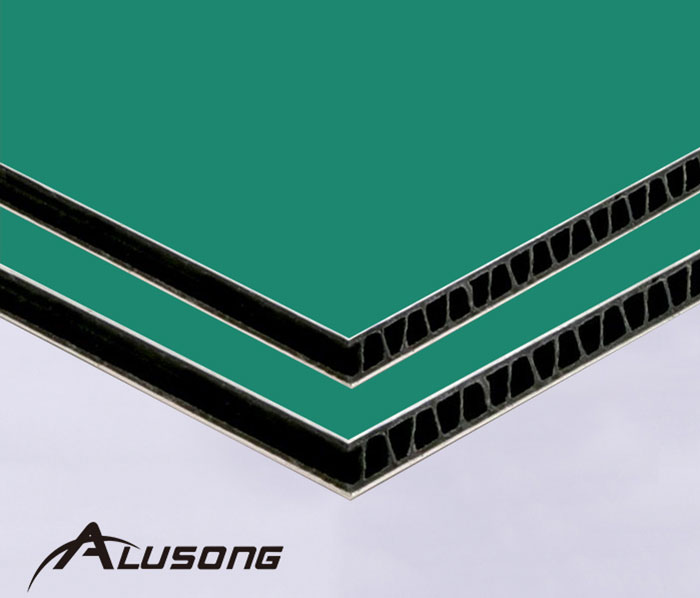

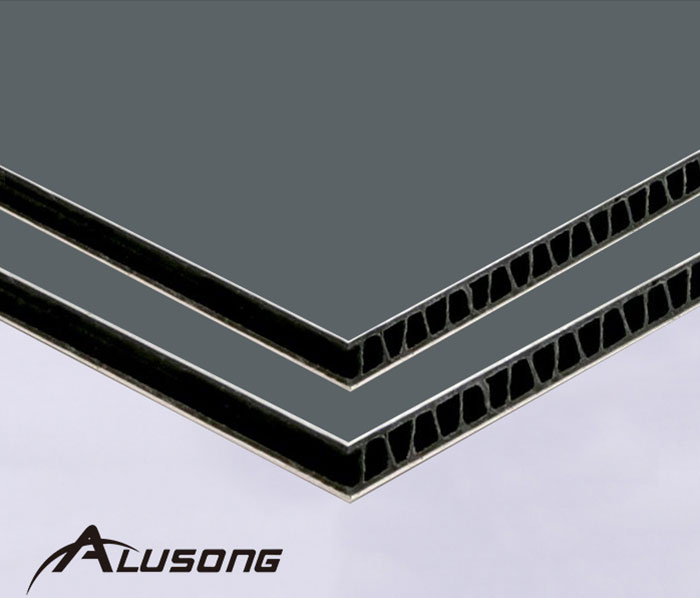

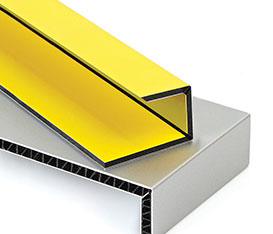

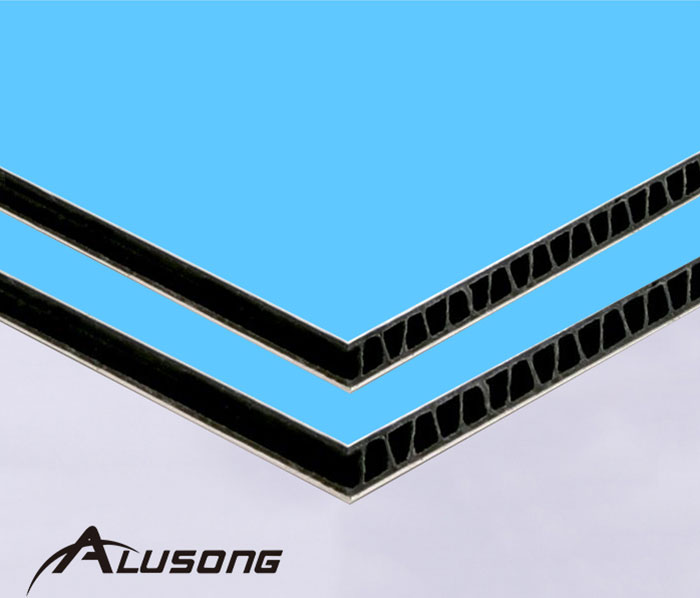

ALUSONG panel features a corrugated plastic core sandwiched between two 0.30mm aluminium skins coated with a superior polyester paint finish. This innovative core structure makes a strong, lightweight panel, offering easy handling and providing maximum strength and stability. ALUSONG panel has an easy-peel protective film and is the perfect base for vinyl. The panels are rigid, easy to install and can be easily fabricated for folding and forming. They are much lighter than standard Aluminium Composite Panels making them ideal for many applications.

ALUSONG panel are painted by a high-gloss, factory-baked, polyester paint coating.

The finish is smooth, durable and dirt resistant. It will not crack, chip, flake or peel even under harsh weather conditions. Colors shown are as the same as ALUSONG other products series as per customer’s request.

| Aluminum | AA1100 AA3003 |

| Aluminum skin | 0.30mm,0.35mm,0.40mm,0.45mm,0.5mm |

| Panel thickness | 4mm,5mm,6mm |

| Panel width | 1220mm |

| Panel length | 2440mm |

| Surface treatment | Polyester |

| Colors | 70 colors, special colors available upon request |

| Customers size | accepted |

| Glossy | 20%-80% |

Dimensional tolerance:

Panel width: ±2mm Panel length:±3mm

Panel thickness: ±0.2mm Panel diagonal: ≤5mm

Aluminum sheet thickness: ±0.01mm

· Field-tested through extensive freeze/thaw cycling tests with no significant structural panel failure

· Ideal for paints, digital inks (both UV or solvent cured), screen print inks, and pressure-sensitive vinyl

· Strong and lightweight, ALUSONG is the same weight as 1mm aluminum sheet metal yet 50 times stronger, 3.5kg per square meters

· Routs and cuts easily using standard carpentry tools; even bends around corners

· Wind-resistant—when properly fastened between two posts, ALUSONG can withstand winds over 120 mph

· Super weather-resistant

· Sign Making, Way finding

· Direct UV & Screen Printing

· Standoff Lettering

· Lightweight Hanging Signs

· Displays &Vinyl Application

· Modular Sign Systems

· Hoarding Panels

· Exhibition Design

· Outdoor Advertising

-

Application

-

Application

-

Application

-

Application

-

Application

| Description | Test standard | Polyester |

| Thickness of coating | Polyester paint >=16um | 16um to 18um |

| Coating flexibility (T-bend) | Polyester paint≥3T | 3T |

| Color different | ΔE≦2.0(follow color sample) | ΔE≦2.0 |

| Pencil hardness | ≧HB | ≧2H |

| Chemical resistance | 2%HCI or 2%NaOH test in 24 hours -No change | No change |

| Coating adhesion | ≧1grade for 10810mm2gridding test | 1grade |

| Resist solvent | 100times with Dimethylebnzene without change | No change |

| Boiling water resistance | 2 hours without change | No change |

| Peeling strength/stripping strength | Average ≧5N/mm of 180oc peel off for panel with 0.21mm alu.skin | 5N/mm |

| Impact test for paint | 20KG.cm impact-paint no split for panel | No split |

| Abrasion resistance (L/Mil) | NIL | NIL |

| Temperature resistance | -40℃ to +80℃ temperature without change of color difference and paint peel off,peeling strength average dropprate≦10% | Change of glossy only,no paint Peel off |

| Cofficient of linear Thermal Expansion | 100℃ temperature difference | 2.4mm/n |

| Detergent resistance (3%) | ASTM D2248 | No change |

| Humidity Resistance (3000hrs,100%RH,100°F) | ASTM D2247 | No change |

| Salt spray resistance (3000hrs,5% salt) | ASTM B117 | No change |

| Resistance to Staining | 600h radiate in 800W/M2 in humidity condition,glossiness deviation less grade 2,color difference ≦4.0 | No change |